Our façade elevators are available in 1500 kg and 2000 kg capacities, all equipped with motor control via frequency inverters. The internal cabin dimensions are 1400 × 2700 × 215 cm, and for the 2-ton model, 1400 × 3000 × 215 cm. A 250 kg capacity tower crane and a 1000 kg capacity façade hoist are also currently under development. Motor power options include 2 × 5.5 kW and 2 × 7.5 kW, providing an operating speed of 36 meters per minute.

Floor Planning is standard and allows the elevator to stop automatically at the next floor. Optionally, with an encoder and remote access-enabled PLC, the elevator can be upgraded to a “smart lift,” enhancing control and efficiency.

Landing Doors are interlocked to prevent opening unless the cabin is at floor level. Similarly, the cabin does not move if the door is open.

Optional floor control panels are available for both call and send operations from each floor.

The control panel on the base enclosure ensures that the door cannot be opened until the cabin has reached the ground level, and stops movement once it does.

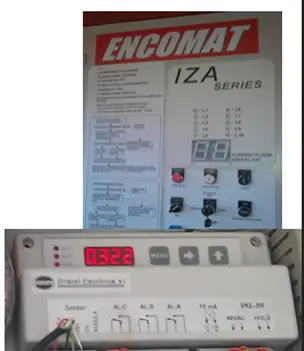

The overload control system displays the total load on the panel and prevents operation if the declared load is exceeded, until the overload switch resets.

Masts are manufactured with ST44.3-grade steel and are coated with hot-dip galvanization for enhanced durability.

Copy@2024 Adım Adım Dijital